Acids and Alkali

Various, highly corrosive fluids are used in the chemical industry. It is important to select a safety shield design and material which is compatible with the process. For example, for PTFE-lined pipeline, it follows that flange guards should also have the relevant PTFE coating. It would be impossible to list every process chemical used, but typical applications include acetic acid, aluminium sulphate, hydrochloric, Nitric, oleum, phosphoric, sodium hydroxide, Sulphuric, titanium tetrachloride.

For acids and alkali applications we recommend the following materials;

Recommended

Recommended

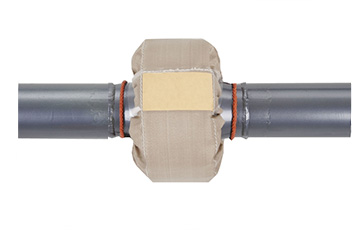

All PTFE shield with Pressure Diffusion Technology (PDT) incorporating multi-layered PTFE mesh. No pull-cords, quick connection. Litmus indicator patch included

Teflon (PTFE)

The PTFE guard is manufactured from three layers of woven Teflon coated fibreglass fabric with a central Teflon scrim for strength. This material is inherently resistant to Ultra-Violet radiation. There is a litmus leak indicator patch contained within a clear Teflon window.

Clear Teflon (ECTFE)

The Clear ECTFE guard is manufactured from a central section of clear teflon & side sections of teflon coated fibreglass. This material is inherently resistant to Ultra-Violet radiation & enables a visual inspection of the flange joint.