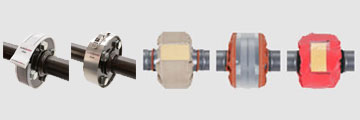

Welcome to FLANGEGUARDS leading manufacturer and supplier of pipe safety shields

Pipe safety shields also known as flange guards are used in a variety of industries, where their primary application is the prevention of harmful spray-outs and mist formation from failing pipe joints, of toxic, corrosive and dangerous liquids such as acid, oil or steam.

Safety or spray shields offer the last line of defence. They are not designed to contain the leak indefinitely, but to prevent the harmful spray outs resulting in fire or explosions causing considerable plant down time, capital expenditure and even loss of life.

If you have a technical question about our products please contact us.

Buy FLANGEGUARDS online

To locate the correct shield for your requirements, please start by selecting a Shield Material, Application or Industry

Select shields by Application

Acid / Alkali, Steam, Thermal Oil, Marine Solas,

Oil Mist and Gas Jet